home page > Product Center >> Drying equipment series >> Complete drying equipment for cattle mattress

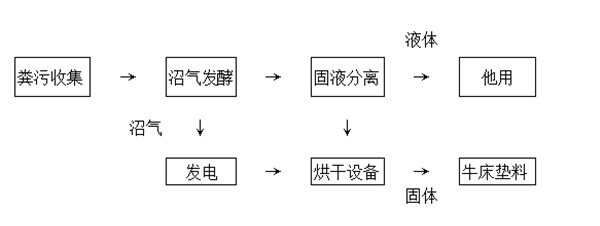

Product introduction: in recent years, our company and some large-scale pastures in China have three production modes of padded utilization of cow dung resources, including solid-liquid separation, direct utilization, anaerobic fermentation and aerobic fermentation. The material characteristics, moisture content, pathogenic bacteria, parasitic eggs and other parameters of finished products treated by different processes, as well as their impact on cow comfort, health and feeding cost, The key technical links such as water control, sterilization and disinfection in the production process of cattle bed recycled bedding have been explored and practiced, and a special R & D team has been established to tackle the technical bottlenecks to be solved and the special equipment required by industrial technology for solid cow dung as bedding, which has been popularized and applied in some large pastures in China.

Working principle: the working principle of the cattle mattress dryer is that the cold air enters the hot blast stove from the end of the hot blast stove through the inlet pipe at an appropriate rotation speed, mixes with the flame burned by the burner to form high-temperature hot air, and enters the special biogas residue dryer of the rotary drum together with the material fed by the feeder through the hot blast pipe, The main body of the dryer is a horizontal cylinder with adjustable speed within a certain range. The materials are exchanged with the hot air when the plate reader evenly distributed in the inner cylinder is turned. The materials are evenly distributed in the dryer and fully contacted with the hot air passing through the cylinder, which speeds up the mass and heat transfer of drying, so as to achieve the purpose of drying.

Under the rotation of the drum, the materials move from the flowing hot air to the rear end. The materials are separated by the cyclone separator adopted by the system, and the collection rate is more than 99%. The fine powder collected by the cyclone separator is discharged from the cyclone discharge port and enters the rear end for utilization. The separated moisture enters the terminal dust removal equipment and is discharged. Temperature, voltage and current display, recording, alarm and electrical starting interlocking procedures are set at important parts of each process.