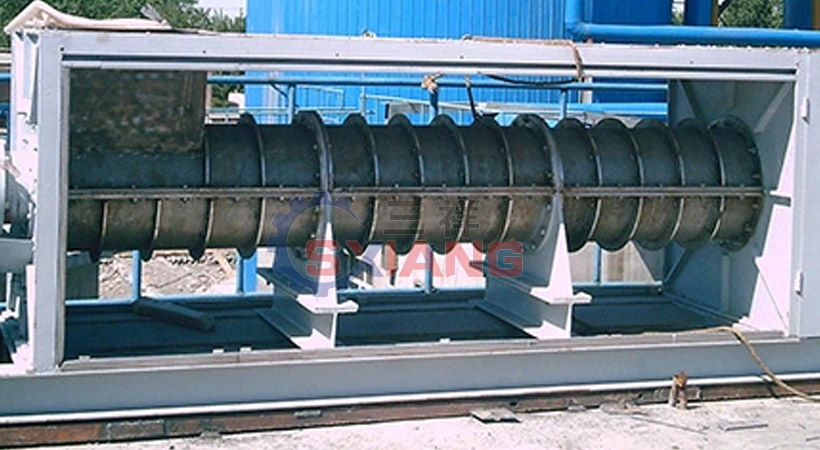

Product introduction: spiral extrusion dehydrator is a main equipment for coagulation and dehydration. It is mainly composed of screw, cylindrical cage shell and cone. The screw shaft is connected with the output shaft of reducer by flexible coupling. The screw extrusion dehydrator can be widely used in the dehydration of high wet residue materials before drying.

工作原理:

1. Rotary filtration: the sludge is flocculated by flocculant to form a floc with a certain strength. The solid-liquid mixture containing a large amount of free water enters the rotary filter through the overflow port of the vertical reactor. The sludge moves forward under the push of the spiral shaft blades. Due to the action of gravity, the drum turns opposite to the spiral, causing the sludge to roll continuously in the drum, The free water inside the floc is continuously filtered out, and the concentrated sludge is pushed to the middle discharge port through the spiral blade to enter the next dehydration process.

2. Screw extrusion: after the pre dewatered sludge enters the screw extruder through the feed hopper, the sludge will compress the volume of the material liquid under the action of the taper screw shaft and the variable diameter screw, so that the water in the material liquid will be quickly separated through the porous filter cartridge, and the water content of the solid will gradually decrease under the action of continuous compression to become the filter cake we need, Then it is discharged out of the machine under the action of screw conveying.